Sammer Alomair

Associate Petroleum Engineering System Analyst

Saudi Aramco

Abdulaziz Alsultan

Lead Operations Producing Advisor

Saudi Aramco

Mohammed Mukhtar

Senior Petroleum Engineer

Saudi Aramco

Ahmed Alqahtani

Senior Petroleum Engineering System Analyst

Saudi Aramco

Sammer Alomair

Associate Petroleum Engineering System Analyst

Saudi Aramco

Abdulaziz Alsultan

Lead Operations Producing Advisor

Saudi Aramco

Mohammed Mukhtar

Senior Petroleum Engineer

Saudi Aramco

Ahmed Alqahtani

Senior Petroleum Engineering System Analyst

Saudi Aramco

PetroBot, a cutting-edge chatbot designed for oil and gas production engineering, aims to revolutionize the way production engineers work by acting as an engineering assistant. This article explores the development, deployment, and future vision of PetroBot, highlighting its potential to significantly enhance performance and efficiency in production engineering tasks.

What Does PetroBot Do?

The energy industry is constantly evolving, and production engineers face the challenge of managing vast amounts of data and complex workflows. PetroBot is designed to address these challenges by providing instant access to curated knowledge bases, extracting key metrics, and answering technical questions. The objective is to investigate the viability of integrating PetroBot into production engineering operations to reduce time spent on routine tasks, improve decision-making, and boost accuracy.

How Does PetroBot Add Value?

PetroBot adds significant value to a production engineer’s day-to-day work in several concrete ways:

Instant Access to Information: Production engineers often spend considerable time searching for specific information across various documents and databases. PetroBot provides instant access to curated knowledge bases, allowing engineers to find the information they need within seconds rather than hours. This efficiency enables engineers to focus on more critical tasks and decision-making processes.

Accurate Data Extraction: Manual data extraction is prone to errors and inconsistencies. PetroBot automates this process, ensuring that key metrics and technical data are accurately extracted and presented. This accuracy is crucial for making informed decisions and maintaining operational integrity.

Expert Answers to Technical Questions: Production engineers frequently encounter complex technical questions that require expert knowledge. PetroBot is trained to understand and respond to these questions, providing expert answers that are directly relevant and actionable. This capability enhances the engineer’s ability to troubleshoot issues and optimize operations.

Reduced Time on Routine Tasks: By automating routine tasks such as data extraction, summarization, and information retrieval, PetroBot frees up valuable time for production engineers. This allows them to focus on more strategic and complex tasks, ultimately improving overall productivity and efficiency.

Enhanced Decision-Making: PetroBot’s ability to provide comprehensive summaries and insights from technical documents enables engineers to gain deeper insights and make more informed decisions. This enhanced decision-making capability can lead to improved operational performance and reduced downtime.

How Does PetroBot Work?

A comprehensive literature review and process engineering design were conducted to determine the compatibility of PetroBot with existing systems and parameters, such as document formats, technical specifications, and operational workflows. Simulation studies were performed to verify the model and optimize the system on various parameters, characterizing the relationship between data input, model performance, and user satisfaction.

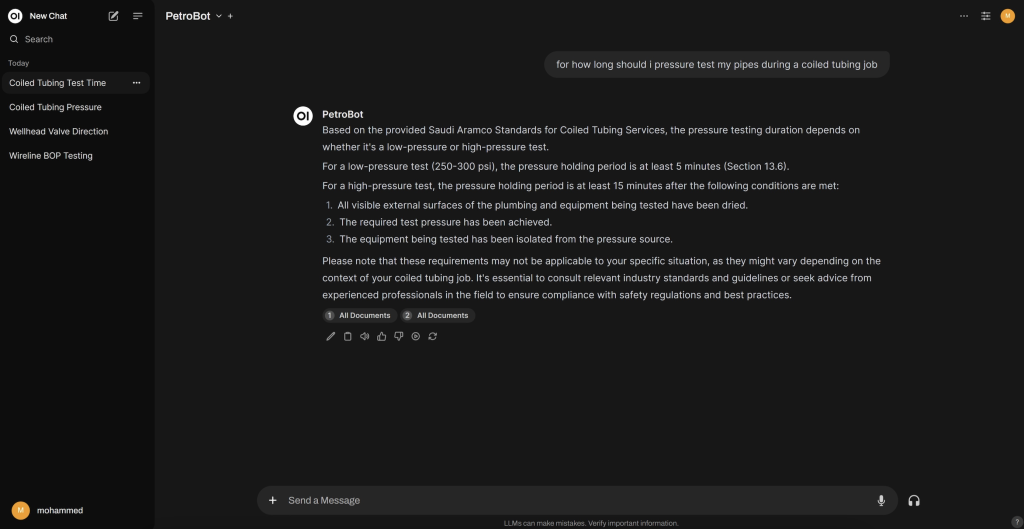

Figure 1: Demonstration of the PetroBot workflow showcasing how the query is processed to produce an expert response

The Results

Simulation results demonstrate promising outcomes. The model has shown the optimal inlet data formats to range from structured documents to unstructured text. Data volume was directly proportional to the accuracy of the generated responses, although at higher complexity levels, that effect is diminished due to the rate of information transfer between the model and the user.

From the wide variety of LLMs available commercially, LLama-7B emerged as the most efficient models due to their high accuracy and low computational requirements. Given an optimal design, PetroBot can yield significant improvements in task completion time and accuracy, benchmarked against traditional methods.

Conclusion

PetroBot presents a sustainable solution for increasing the efficiency and accuracy of production engineering tasks. The system demonstrates significant potential for improving decision-making, reducing time spent on routine tasks, and boosting overall performance. Further research and implementation efforts are warranted to fully realize the benefits of this approach.

Key Recommendations: As we reflect on our journey in developing PetroBot, we’d like to distill some key learnings and recommendations for fellow researchers and practitioners looking to integrate similar AI-powered solutions in their organizations:

Start small: Begin by identifying a specific pain point or use case where AI can bring immediate value. In our case, it was streamlining data extraction and providing expert answers to technical questions.

Collaborate with stakeholders: Engage closely with end-users (in this case, production engineers) to ensure that the tool meets their needs and expectations. Regular feedback loops helped us refine PetroBot’s functionality and user interface.

Curated knowledge bases matter: Invest time in creating high-quality, domain-specific knowledge bases that can serve as a foundation for your AI-powered solution. This will enable accurate and reliable outputs.

Experiment and evaluate multiple models: Don’t settle on a single AI model without exploring alternatives. Our evaluation of different Large Language Models (LLMs) led us to select the most suitable one for PetroBot.

Monitor and adjust: Continuously monitor the performance of your AI solution and gather user feedback to identify areas for improvement. Be prepared to fine-tune and adapt your system accordingly.

By following these guidelines, organizations can accelerate the adoption of AI-driven tools like PetroBot, unlocking new efficiencies and innovations in production engineering and beyond.

Future Vision

The development of PetroBot marks a significant achievement in the field of production engineering. The vision for PetroBot and the roadmap we have created aims to make further improvements, ensuring that the goal of accelerating a production engineer’s job by a significant amount is realized. The team is excited to execute and iterate on this vision, paving the way for a more efficient and effective production engineering workforce.