By Akram R. Al-Barghouti, M. Imran Javed, and Sanjiv Kumar

Southern Area Production Engineering Department, Saudi Aramco

Saudi Aramco’s production engineers are always striving for excellence and innovations. The company’s Southern Area Production Engineering Department (SAPED) tailored a unique program to foster innovations. An example is presented in this article where a journey toward commercialization of an SAPED patent titled “Methods & Tools for Determining Bleed-off Pressure After Well Securement Jobs” has been initiated. The central focus of this endeavor is the development of an advanced wireline tool engineering design, which is intended for field applications. Led by a team of highly skilled and innovative production engineers, extensive efforts have been dedicated to conceptualizing a unique tool design along with accompanying procedures that aim to revolutionize well-securement operations and optimize the efficiency of through tubing bridge plugs (TTBP).

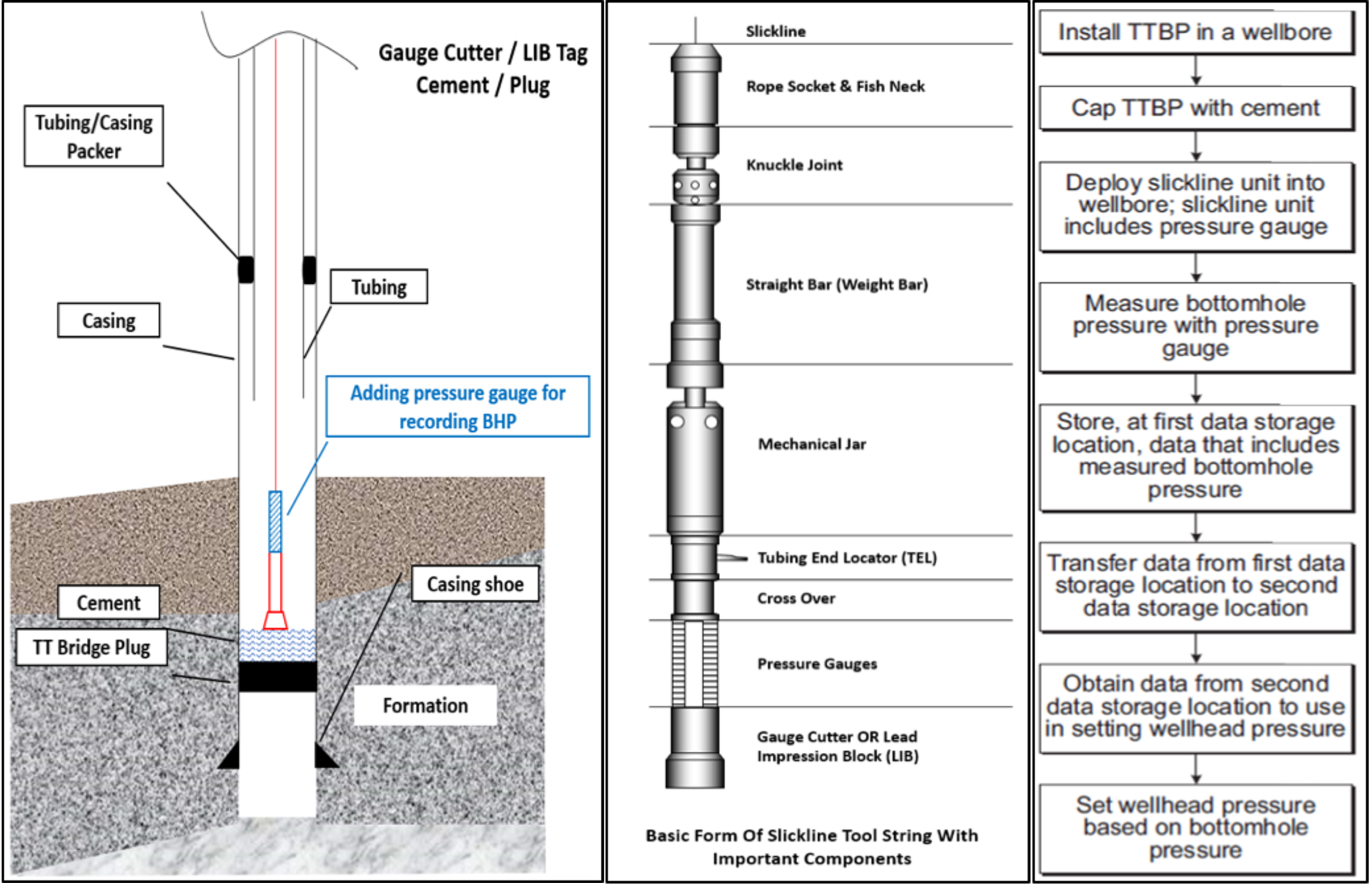

This patented tool design encompasses a range of intricate components, meticulously designed to achieve optimal performance and accuracy. These include a gauge cutter, precisely calibrated weight bars, a sensitive tubing end locator, and an additional tool incorporating advanced pressure gauges. This amalgamation of progressive technology and engineering expertise enables the accurate calculation of downhole (DH) static bottom-hole pressure (SBHP) post well securement. By coupling this information with the parameters of shut-in wellhead pressure (SIWHP), the tool facilitates the calculation of wellhead pressure bleed-off during an inflow test, thereby serving as a robust means to confirm the integrity of the securement plug.

Driven by the commitment to continuous improvement and innovation, SAPED’s engineers are collaboratively working alongside other organizations involved in the project to develop an integrated digital solution. This digital platform aims to automate the wireline tool’s functionality, streamline data acquisition and analysis processes, enable real-time monitoring of crucial well integrity parameters, and empower SAPED engineers with data-driven insights for enhanced decision making. By leveraging the power of automation and digitalization, which are an integral part of its strategy, SAPED strives to ensure the effective utilization of the wireline tool and unlock new dimensions of operational efficiency and excellence.

The significance of well-integrity programs within the oil and gas industry cannot be overstated. These programs serve as the backbone for ensuring the safe and efficient operation of wells across all fields. Central to these programs is the crucial process of well securement, which involves the strategic utilization of tubing bridge plugs to isolate cased hole zones and cap them with a precise amount of cement to safeguard the reservoir. Given the extreme operating conditions and high pressures experienced by these plugs, precise engineering calculations are indispensable for accurately determining the differential pressure across the plugs and maximizing their efficiency.

The successful implementation and commercialization of the newly developed wireline tool design hold tremendous potential for the oil and gas industry. By mitigating securement plug failures, minimizing rig workover complexities, and optimizing operational efficiency for both rig and rigless interventions, significant cost savings can be realized. This technological breakthrough is expected to result in increased production uptime, reduced unplanned downtime, and enhanced overall operational performance, thereby generating substantial value for oil and gas companies.

In addition to the direct operational benefits, SAPED recognizes the broader industry implications of this innovation. By sharing the innovative wireline tool design, its associated job scope, and implementation strategies with other industry competitors, SAPED aims to foster knowledge sharing, promote collaboration, and accelerate the adoption of best practices across the sector.

To ensure the successful realization of this ambitious endeavor, SAPED has meticulously planned the project timeline. The aim is to finalize the tool concept design while simultaneously commencing field trials. These trials will play a pivotal role in validating the performance, reliability, and functionality of the wireline tool under real-world conditions. The invaluable insights and data gathered from these field trials will enable SAPED’s engineers to refine and optimize the tool’s design, guaranteeing that the final product meets the highest standards of accuracy, durability, and effectiveness.

SAPED’s relentless pursuit of becoming a premier production engineering entity is exemplified by this transformative initiative. By synergizing innovative engineering design, collaborative efforts with industry peers, and the integration of latest digital solutions, SAPED aims to make a lasting impact on well integrity programs and operational excellence. This forward-thinking approach, characterized by cost optimization, enhanced efficiency, and an unwavering commitment to industry-wide collaboration, positions SAPED at the forefront of production engineering, and ready to spearhead a new era of progress and innovation in the oil and gas industry.

Diagram and process chart illustrating the functionality and procedure of the wireline tool

Figure 1